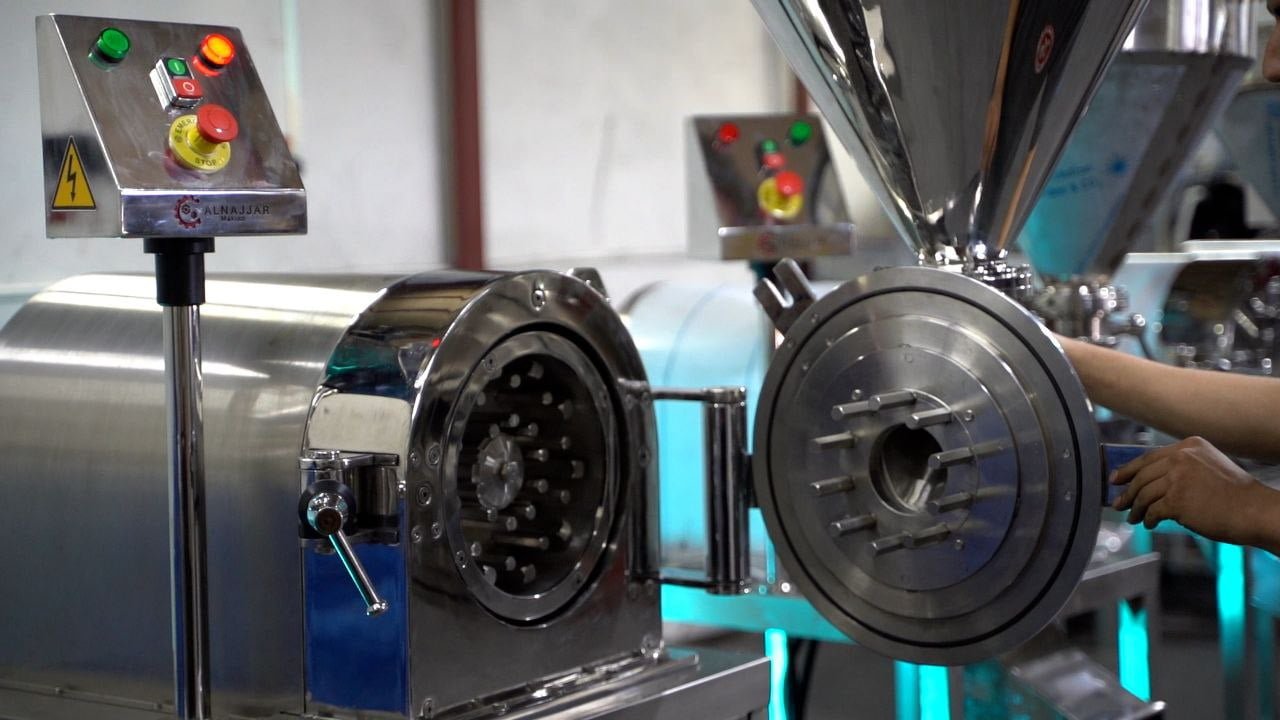

Capacity : 250 kgs / hour , Motor power : 7.5 Kw VFD Converter

Here are key aspects of the Multi Mill:

1. Principle of Operation: The multi mill operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the desired size reduction.

2. Versatility: It is a versatile machine that can be used for various processes such as milling, granulation, pulverization, and blending.

3. Size Reduction: Multi mills are widely used for reducing particle size of pharmaceutical ingredients, chemicals, dyes, and food products. They are particularly effective in achieving uniform particle size reduction.

4. Interchangeable Screens: The machine comes with interchangeable screens of different mesh sizes, allowing for control over the particle size of the final product.

5. Variable Speed: Many multi mills are equipped with variable speed controls, enabling operators to adjust the speed as needed for different materials and processes.

6. Granulation: In addition to size reduction, Multi Mills are used for wet and dry granulation processes in pharmaceutical manufacturing. The machine can convert powders into granules for further processing.

7. Pulverization: Multi Mills are effective for pulverizing materials into fine powders. This is crucial in various industries where finely powdered substances are required.

A Multi Mill is a versatile pharmaceutical machinery used for multiple processes in the pharmaceutical, chemical, cosmetic, and food industries. It is designed for size reduction, granulation, pulverization, and blending of powders and granules.

8. Blending:Multi Mills can be used for blending different powders or granules to achieve a homogenous mixture. This is important in industries where uniformity in composition is critical.

9. Ease of Cleaning: The design of Multi Mills often incorporates features for easy disassembly and cleaning between batches, meeting hygiene standards in pharmaceutical manufacturing.

10. Pharmaceutical Applications: – In pharmaceutical manufacturing, Multi Mills find applications in processes like tablet granulation, tablet coating, and production of pharmaceutical powders.

11. Safety Features: Many modern Multi Mills are equipped with safety features to prevent accidents during operation. These features may include interlocks and safety guards.

12. Scale-Up Capability: -Multi Mills are available in various sizes to accommodate different production scales. This scalability makes them suitable for both laboratory and industrial applications.

13. Material of Construction: Multi Mills are often constructed with materials that comply with pharmaceutical and food-grade standards to ensure the purity of the processed materials.

In summary, the Multi Mill is a versatile and widely used machine in pharmaceutical and other industries for size reduction, granulation, pulverization, and blending of powders and granules. Its ability to perform multiple processes in a single machine makes it an essential tool in various manufacturing settings.If you are looking for bracelet. There’s something to suit every look, from body-hugging to structured, from cuffs to chain chain bracelet and cuffs.