Al Najjar Machinery specializes in manufacturing Filling Machines for pharmaceutical syrup production lines.

The Filling Machines produced by Al Najjar Machinery are specifically designed to meet the needs of pharmaceutical syrup production. They offer the following features:

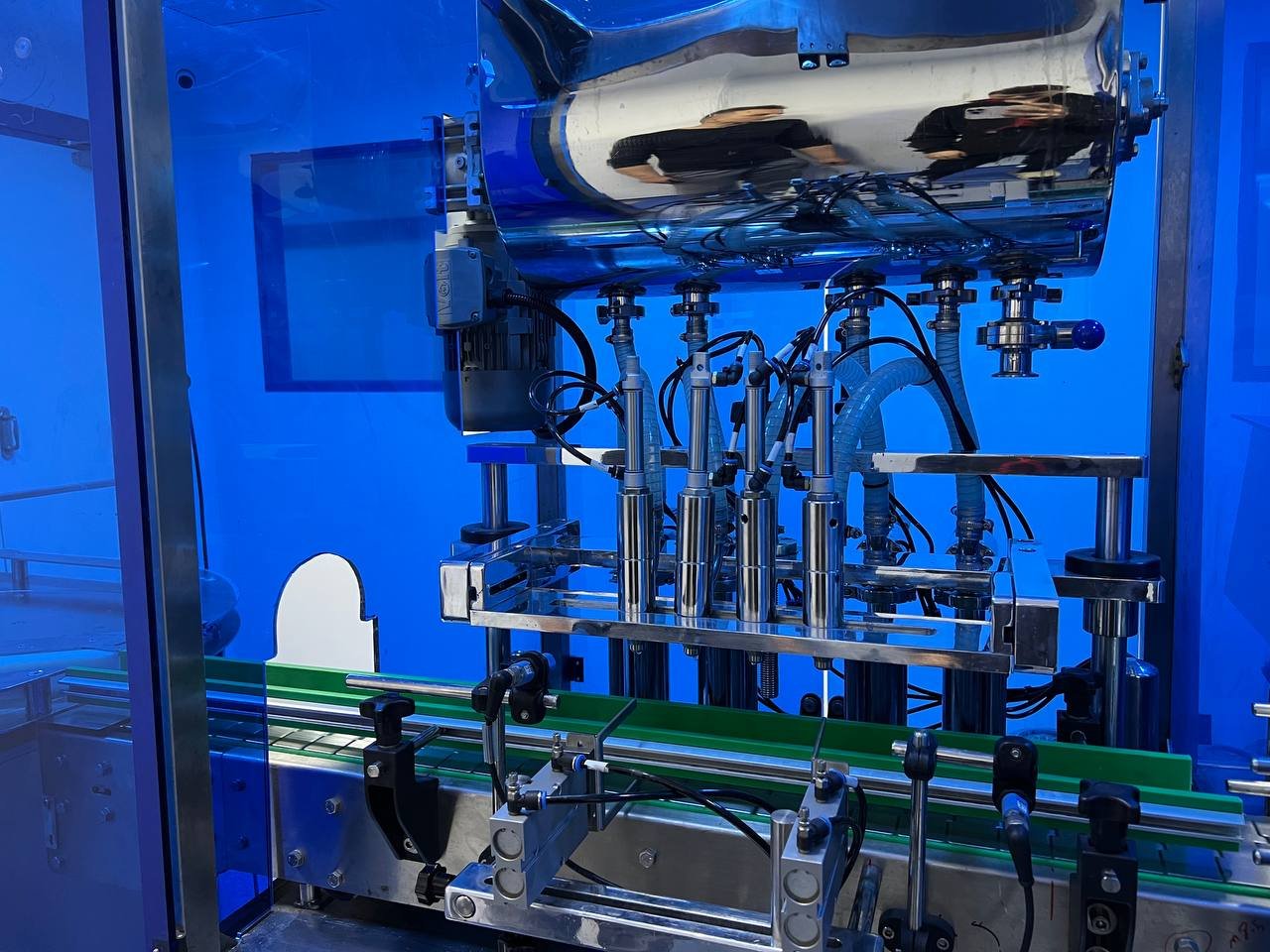

- Accurate and Precise Filling: The Filling Machines are equipped with advanced technology and precision control systems to ensure accurate and consistent filling of pharmaceutical syrup into bottles. They are designed to minimize wastage and ensure precise volume control

- Compliance with Regulatory Standards: Al Najjar Machinery prioritizes compliance with regulatory standards in the pharmaceutical industry. The Filling Machines are designed to meet the necessary quality and safety regulations, ensuring that the filling process adheres to industry guidelines.If you are in the market for superclone Replica Rolex , Super Clone Rolex is the place to go! The largest collection of fake Rolex watches online!

Syrup Filling Machine

-

-

- Hygienic Design: The Filling Machines are designed with hygiene in mind. They feature sanitary construction materials and smooth surfaces that are easy to clean and maintain. This ensures compliance with strict hygiene standards and minimizes the risk of contamination during the filling process.

-

-

-

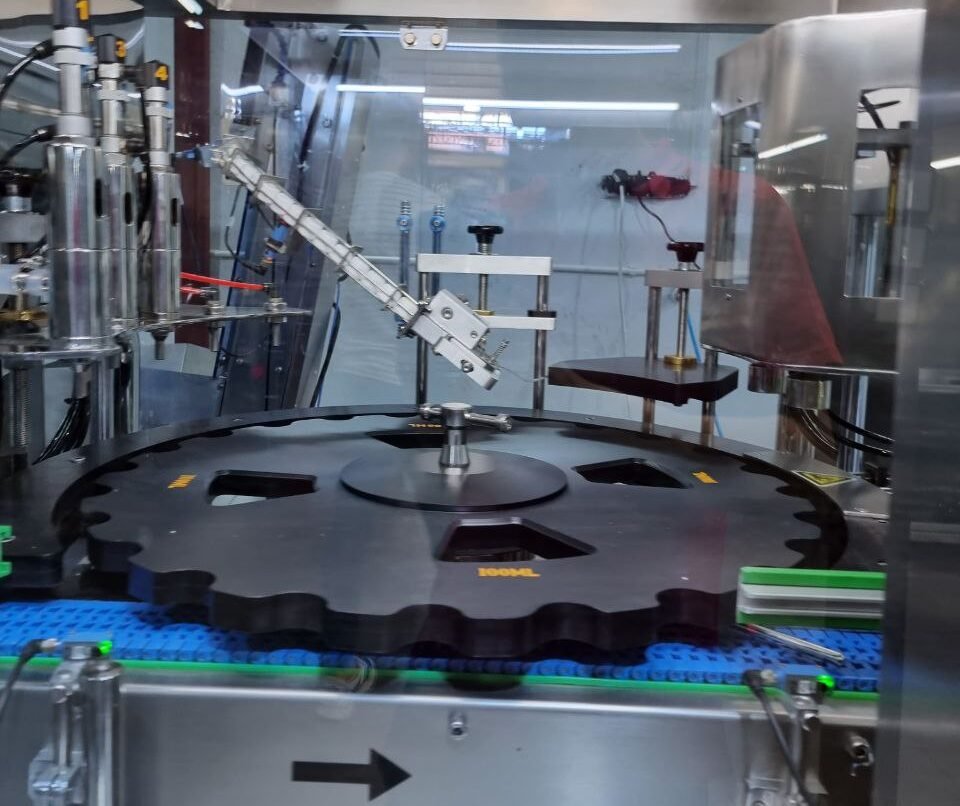

- Customizable Solutions: Al Najjar Machinery understands that different pharmaceutical syrup production lines may have unique requirements. Therefore, the Filling Machines can be customized to meet specific production needs, including filling speed, bottle size, and filling volume.

-

- Versatile Filling Options: Al Najjar Machinery’s Filling Machines can handle various bottle sizes and shapes commonly used in pharmaceutical syrup production. They are adaptable to different types of bottles, including glass and plastic, and can accommodate different filling techniques, such as gravity filling or piston filling.

By choosing Al Najjar Machinery’s Filling Machines, pharmaceutical syrup manufacturers can benefit from reliable and efficient filling solutions. The machines offer accurate and precise filling, versatility in handling different bottle types, hygienic design, and compliance with regulatory standards. This contributes to streamlined production processes, product integrity, and adherence to industry regulations.