The Manufacturing of Cosmetics: Essential Equipment and Processes

Cosmetics have played a pivotal role in human society for centuries. From ancient civilizations using natural substances to modern-day labs creating innovative formulas, the manufacturing of cosmetics has come a long way. Behind the scenes, there’s a complex process involving specialized equipment. In this blog, we’ll explore the key equipment used in the manufacturing of cosmetics and how it contributes to creating the products we use daily.

Mixing Tanks and Emulsifiers

One of the initial steps in cosmetic manufacturing involves blending various ingredients to create a uniform mixture. Mixing tanks, typically made of stainless steel or other corrosion-resistant materials, are essential for this process. They vary in size, ranging from small tanks for lab-scale production to large vessels for mass production.

Emulsifiers play a crucial role in creating stable emulsions, which are a combination of oil and water-based ingredients. These devices use high shear forces to break down and mix different components, ensuring that the final product is smooth and well-integrated.

Homogenizers

Homogenizers are used to further refine emulsions and ensure a consistent texture. They work by applying high pressure and mechanical force to break down particles and create a uniform blend. This step is vital for products like lotions and creams, where a smooth, creamy texture is desired.

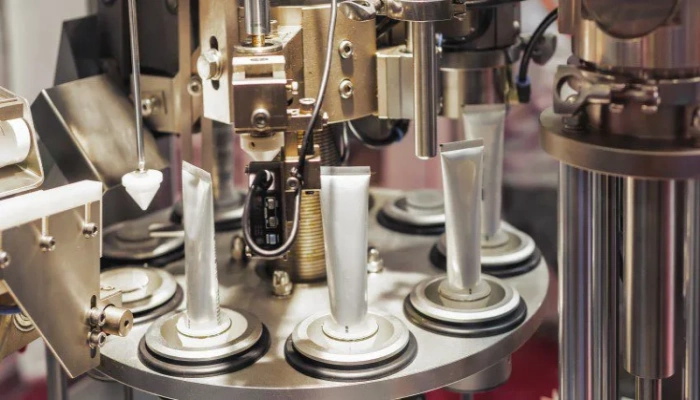

Filling and Packaging Machinery

After the formulation is perfected, the next step is to package the product. This involves various types of machinery:

- Filling Machines: These machines accurately dispense the product into its final container, whether it’s a bottle, jar, tube, or any other type of packaging. They are designed to handle a wide range of viscosities and consistencies.

- Capping Machines: Once the product is in its container, it needs to be sealed. Capping machines come in different types, including screw cappers, snap cappers, and crimp cappers, depending on the type of closure used.

- Labeling Equipment: This equipment applies labels with product information, branding, and regulatory requirements. It’s essential for compliance and brand recognition.

Quality Control Tools

Ensuring the quality and safety of cosmetic products is of paramount importance. Various tools and equipment are employed for quality control:

- Viscosity Meters: These instruments measure the thickness or viscosity of a liquid, ensuring that it meets the desired specifications.

- pH Meters: pH levels are critical for the stability and effectiveness of many cosmetic products. pH meters help maintain the desired acidity or alkalinity.

- Microbial Testing Equipment: This includes tools for detecting and quantifying microorganisms in the product, ensuring it’s free from harmful bacteria or pathogens.

Mixing and Dispensing Equipment

For products like nail polish, lipsticks, and powders, specialized equipment is required:

- Agitators and Mixers: These machines are used to blend pigments, dyes, and other ingredients into the base formulation.

- Pressing Machines: In the case of pressed powders, these machines are used to compact the powder into a solid form that fits into a compact.

Cleanroom and Sterilization Equipment

In some cases, especially for products that are applied to sensitive areas of the body, maintaining a sterile environment is crucial. Cleanrooms are specially designed, controlled environments that prevent contamination during the manufacturing process. Sterilization equipment ensures that the final product is free from harmful microbes.

Conclusion

The manufacturing of cosmetics is a highly sophisticated process that relies on a range of specialized equipment. From mixing tanks to quality control tools, each piece of machinery plays a crucial role in creating high-quality, safe, and effective cosmetic products. As technology continues to advance, we can expect even more innovative equipment to shape the future of cosmetic manufacturing.

Cosmetics manufacturing machines

Liquid Detergent Shampoo Mixer Making Machinery

It seems like you’re asking about machinery used in the production of liquid detergent and shampoo. These types of machines are commonly used in the manufacturing industry for blending and mixing various ingredients to create liquid products like detergents and shampoos.

Cosmetic cream filling machine

A cosmetic cream filling machine is a specialized piece of equipment used in the cosmetic industry for efficiently and accurately filling various types of creams, lotions, gels, and other cosmetic products into containers.

These machines are designed to handle the specific viscosity and texture of cosmetic creams.